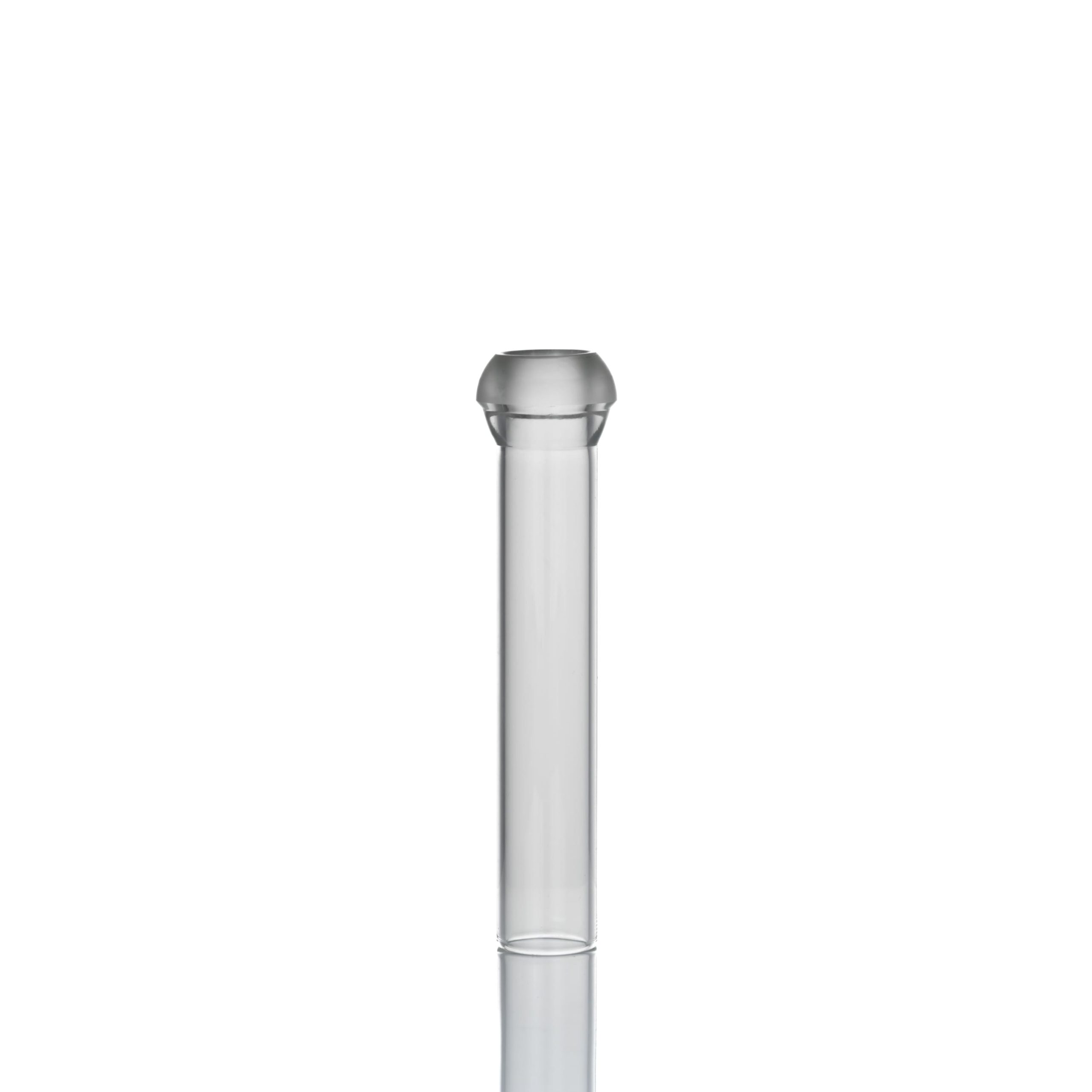

Description

| Catalogue No. | Joint Size | Code App. Bore | Shank L. |

| 11105/1 | S13 | 5 | 100 |

| 11105/2 | S19 | 9 | 100 |

| 11105/3 | S29 | 15 | 100 |

| 11105/4 | S35 | 19 | 100 |

| 11105/5 | S41 | 27 | 100 |

| 11105/6 | S51 | – | – |

The MEDILAB Spherical Ground Joint (Ball) is a precision-crafted, interchangeable glass joint designed to ensure secure, leak-free connections in laboratory assemblies. It is widely used in distillation setups, reaction systems, condensers, and modular glass apparatus. The spherical shape provides excellent alignment tolerance, making it ideal for applications requiring flexible joint angles and repeatable sealing performance. Its accuracy and reliability make it indispensable in research, industrial, and analytical environments.

Key Features

- Manufactured from high-purity Borosilicate Glass 3.3 for exceptional chemical and thermal stability

- Precision-ground spherical surface ensures tight, leak-resistant fittings

- Complies with DIN 12264 standards for interchangeability and dimensional accuracy

- Smooth grinding finish for consistent performance and reduced wear on mating components

- Excellent resistance to thermal shock, acids, solvents, and routine laboratory cleaning agents

- Designed for long service life in demanding laboratory and industrial operations

- Compatible with standard socket counterparts across global laboratory glassware systems

Material Specifications

- Material: Borosilicate Glass 3.3

- Thermal Properties:

Low coefficient of thermal expansion (~3.3 × 10⁻⁶ /K)

High thermal shock resistance, suitable for controlled heating applications - Chemical Resistance:

Highly resistant to most acids, alkalis, and organic solvents

Non-porous surface prevents contamination and ensures ease of cleaning - Mechanical Strength:

Strong structural integrity with resistance to mechanical stress during assembly - Standards & Compliance: Meets international laboratory glassware quality norms (ISO/DIN equivalents)

Technical Specifications

- Available Sizes:

Standard Spherical Joint sizes: S12 to S51 (as per the standard size table) - Dimensions:

Manufactured according to DIN standards, ensuring compatibility with standard sockets. Precision-ground tolerance for uniform fit - Tolerance/Accuracy:

Ground joint finish ensures high sealing accuracy and repeatability - Accessories:

Compatible with MEDILAB spherical joint clamps and sockets (sold separately)

Custom sizes and OEM configurations available on request

Handling & Precautions

- Handle with care to avoid chipping of the ground spherical surface

- Clean using mild detergents or suitable laboratory glass cleaning agents

- Autoclavable at standard lab autoclave conditions; avoid rapid temperature changes

- Do not expose to direct flame or sudden thermal shocks

- Always ensure matched joint sizes for proper sealing and stability

- Store in padded racks or protective sleeves to maximise service life

Applications

- Chemical, Pharmaceutical & Biotech Laboratories

Distillation, reflux, concentration, and reaction assemblies - Academic & Research Institutions

Modular experimental setups requiring frequent assembly/disassembly - QC/QA & Analytical Labs

Precision workflows where leak-free glass connections are critical - Industrial R&D Facilities

Pilot-scale reactions, process development, and custom glass apparatus - Ideal for any environment requiring reliable, interchangeable glass joints with high chemical resistance and dimensional accuracy