Description

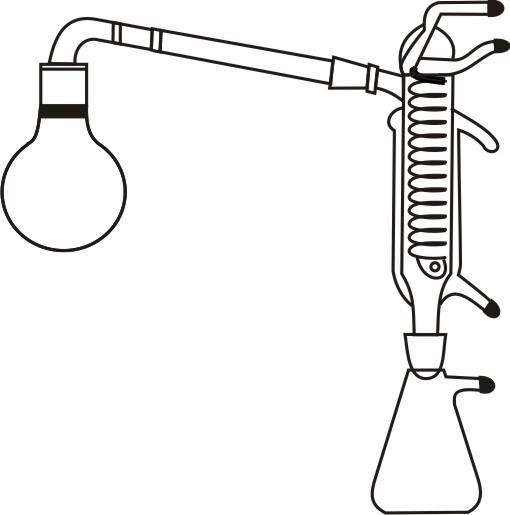

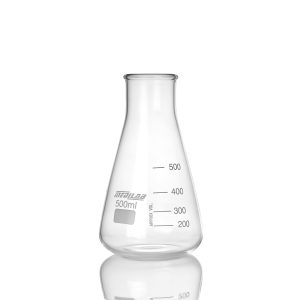

A Solvent Recovery Assembly is a setup used in a laboratory or industrial setting to recover solvents for reuse. Solvents are often used in various chemical processes and can be expensive to continuously purchase. The recovery of used solvents can reduce waste and costs. The assembly typically consists of a distillation flask, a condenser, a collection flask, a heating source, and a vacuum source.

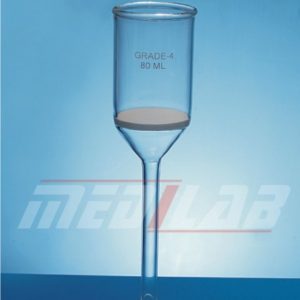

The distillation flask holds the mixture of solvent and impurities, the condenser cools and condenses the vapor produced during distillation, the collection flask collects the purified solvent, the heating source provides the necessary heat to boil the mixture, and the vacuum source reduces the pressure in the distillation flask, allowing for more efficient distillation.

The Solvent Recovery Assembly works by heating the mixture of solvent and impurities, causing the solvent to vaporize and be carried away by the vapor. The condenser then cools the vapor, causing it to condense into a purified liquid, which is collected in the collection flask.