Description

| High Alumina, Pot/Bead Mill | |

| Catalog Number | Loading Capacity (ml) |

| 19511/01 | 200 |

| 19511/02 | 500 |

| 19511/03 | 1000 |

| 19511/04 | 2000 |

| 19511/05 | 3000 |

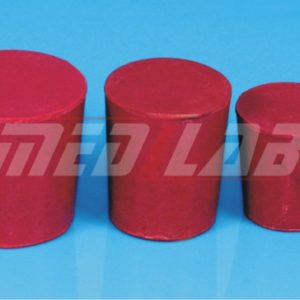

The MEDILAB Pot/Bead Mill is a high-performance grinding vessel made from premium alumina, engineered for precision milling, dispersion, homogenization, and particle-size reduction. Its round, unglazed construction provides excellent abrasion resistance and minimal sample contamination, making it indispensable for demanding laboratory and industrial grinding applications. Designed for reliability under continuous use, it ensures stable, repeatable results across analytical and production environments.

Key Features

- Manufactured from high-purity alumina for exceptional durability and chemical stability.

- Unglazed interior surface provides optimal grinding efficiency and reduced slippage.

- Round, seamless design minimises weak points and enhances structural integrity.

- High wear resistance, ideal for long-term milling of hard and abrasive materials.

- Low contamination performance, suitable for sensitive analytical workflows.

- Excellent thermal properties, enabling use in heated milling environments.

- Inert to most chemicals, ensuring compatibility with a wide range of samples.

Material Specifications

- Material: High Alumina (Al₂O₃)—typically 95–99.5% purity

- Thermal Properties:

High-temperature stability

Excellent thermal shock resistance - Chemical Properties:

Resistant to acids, alkalis, solvents, and organic compounds - Mechanical Properties:

High hardness, toughness, and abrasion resistance - Manufacturing Standards:

Produced under ISO-compliant ceramic quality controls

Meets general laboratory ceramic performance norms (ISO/DIN)

Technical Specifications

- Shape: Cylindrical, unglazed pot

- Sizes/Capacities: Available in multiple standard volumes suitable for bead milling systems (custom sizes available on request)

- Tolerances: Precision-formed for consistent dimensional stability

- Surface Finish: Unglazed inside and outside for improved grinding action

- Accessories (Optional):

Alumina beads (various diameters)

Matching alumina lids or covers

Milling supports and trays

Handling & Precautions

- Avoid abrupt temperature changes—allow gradual heating or cooling.

- Clean using mild detergents; avoid metallic scrubbers that can damage ceramic surfaces.

- Prevent mechanical shock, dropping, or edge impacts.

- Use compatible grinding beads to prevent excessive wear.

- Ensure proper alignment in milling machines to avoid uneven load distribution.

- Store in a dry, dust-free location when not in use.

Applications

Perfectly suited for:

- Pharmaceutical formulation development

- Chemical and petrochemical processing

- Biotechnology and enzyme dispersion

- Ceramic, pigment, and catalyst grinding

- QC/QA labs for particle size reduction and homogenization

- University and research laboratories

- Small-scale production R&D and materials science

The Pot/Bead Mill supports essential workflows, including sample refinement, dispersion studies, micro-pulverisation, and wet or dry milling.