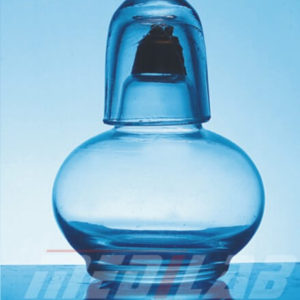

Description

| High Alumina, Combustion Boat, with Tail and Hole | |

| Catalog Number | Capacity (ml) |

| 19509/01 | 3 |

| 19509/02 | 7 |

| 19509/03 | 15 |

| 19509/04 | 30 |

| 19509/05 | 40 |

| 19509/06 | 500 |

The MEDILAB High Alumina Combustion Boat with Tail and Hole is a precision-engineered ceramic vessel designed for high-temperature analytical processes. It is widely used for combustion, ashing, elemental analysis, and thermal decomposition studies. Its robust high-alumina construction ensures stability, minimal contamination, and accurate results, making it essential for laboratories, research centres, and industrial testing environments.

Key Features

- High-purity alumina composition ensures excellent thermal resistance and chemical inertness.

- Tail and side hole design for easy handling, positioning, and optimized airflow during combustion.

- Stable performance up to extremely high temperatures without warping or deformation.

- Smooth internal surface to minimize sample loss and enhance cleaning efficiency.

- High mechanical strength suitable for repeated heating cycles.

- Low thermal expansion ensures dimensional stability during rapid temperature changes.

- Corrosion- and wear-resistant, ideal for use with oxidizing and reducing atmospheres.

Material Specifications

- Material: High-Purity Alumina (Al₂O₃)

- Thermal Properties:

Excellent thermal shock resistance

Suitable for high-temperature operations (typical alumina limit: ~1600–1700°C depending on grade) - Chemical Resistance:

Highly resistant to acids, solvents, alkalis, and most corrosive environments - Mechanical Properties:

High compressive strength

Superior hardness and abrasion resistance - Compliance: Manufactured in accordance with general ceramic labware standards (ISO/DIN guidelines for technical ceramics)

Technical Specifications

- Design: With a tail and a side hole for controlled heating and easy manipulation

- Available Sizes: Wide range of standard laboratory sizes (custom dimensions available on request)

- Dimensions: Length, width, height, and wall thickness according to application requirements

- Tolerance: Precision-made with consistent dimensional accuracy for repeatable results

- Heating Limits: Suitable for high-temperature furnaces (user must follow furnace manufacturer limits)

- Accessories (Optional):

Tongs, sample holders, furnace supports

Handling & Precautions

- Do not subject the boat to sudden thermal shocks; allow gradual heating and cooling.

- Clean with mild laboratory detergents and rinse thoroughly to avoid residue buildup.

- Avoid using metallic scrapers that may chip the ceramic surface.

- Compatible with furnace and muffle heating (follow maximum temperature guidelines).

- Do not drop or apply excessive mechanical force, as the ceramic can fracture.

- Store in a dry, clean environment to maintain material integrity.

Applications

Ideal for use in:

- Combustion and ashing tests in chemical laboratories

- Elemental analysis (C/H/N/S testing)

- Gravimetric analysis in academic and research institutions

- Organic/inorganic sample decomposition

- Quality control and quality assurance labs (QC/QA)

- Pharmaceutical, chemical, petrochemical, and environmental labs

- Thermal treatment and material testing workflows

Its reliable performance makes it an essential component in day-to-day analytical and experimental operations.