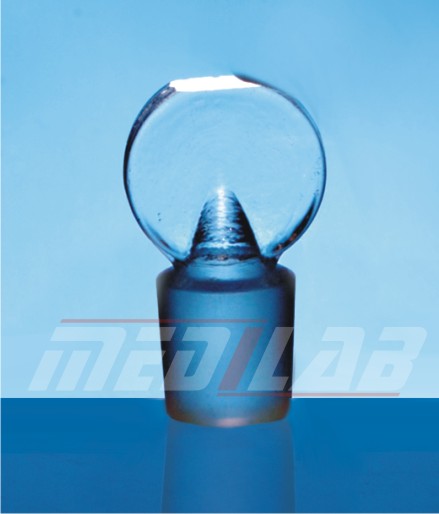

Description

| Catalogue No. | Cone Size |

| 11110/1 | 10/19 |

| 11110/1.1 | 12/21 |

| 11110/2 | 14/23 |

| 11110/3 | 19/26 |

| 11110/4 | 24/29 |

| 11110/5 | 29/32 |

| 11110/6 | 34/35 |

The MEDILAB Solid Glass Stopper, Penny Head, is a precision-made sealing component designed for laboratory glassware requiring an airtight, leak-proof closure. Its distinctive penny-shaped head provides easy grip and controlled handling during routine lab operations. Manufactured from high-quality borosilicate glass 3.3, it delivers superior chemical resistance, thermal stability, and durability—ensuring reliable performance in research, analytical, educational, and industrial environments.

Key Features

- Penny-Head Design: The Ergonomic flat disc head ensures a secure grip and safe handling, even with gloved hands.

- High-Precision Ground Joint: Offers perfect sealing compatibility with standard interchangeable glassware.

- Superior Durability: Made from borosilicate glass 3.3, providing long-term resistance to breakage and thermal stress.

- Chemically Inert Surface: Non-reactive with common acids, alkalis, solvents, and laboratory reagents.

- Smooth Polished Finish: Allows effortless insertion and removal without sticking.

- Universal Fit: Compatible with a wide range of laboratory flasks, bottles, cylinders, and containers using standard taper joints.

- Autoclavable Construction: Safe for sterilisation and repeated high-temperature use.

Material Specifications

- Material: Borosilicate Glass 3.3

- Thermal Properties: Low thermal expansion coefficient (~3.3 × 10⁻⁶/K) Excellent thermal shock resistance

- Chemical Resistance: High resistance to acids, alkalis, organic solvents, and corrosive chemicals. Non-porous, ensuring contamination-free operations

- Mechanical Properties: High-dimensional stability Scratch-resistant and long-lasting

- Standards Compliance: Manufactured in accordance with international glass standards (ISO / DIN equivalents)

Technical Specifications

- Available Sizes: Multiple standard taper joint sizes (custom sizes available on request).

- Dimensions: Precision-ground according to standard joint geometry.

- Tolerance: Tight dimensional tolerances ensure secure, airtight sealing.

- Calibration: Not applicable for solid stoppers.

- Accessories Included: None (compatible glassware available separately).

Handling & Precautions

- Safe Use: Insert gently into matching joints to avoid chipping of ground surfaces. Ensure stopper and joint surfaces are dry for optimal sealing.

- Cleaning Instructions: Wash using standard laboratory detergents and warm water. Suitable for ultrasonic cleaning. Avoid abrasive pads that may scratch the ground surface.

- Autoclaving: Fully autoclavable; withstands repeated sterilisation cycles. Avoid rapid temperature changes to prevent thermal shock.

- Do’s & Don’ts: Do: Rotate gently during removal to prevent sticking. Do: Store in padded compartments to avoid impact damage. Don’t: Use excessive force when inserting or removing. Don’t: Expose to direct flame or sudden extreme heat.

- Best Practices: Lightly lubricate ground joints with appropriate grease when required.

Applications

- Analytical & Research Laboratories: Sealing flasks and vessels in chemical reactions and sample preparation.

- Pharmaceutical QC/QA: Ideal for contamination-free storage of sensitive samples.

- Chemical & Industrial Laboratories: Suitable for processes requiring airtight containment.

- Biotechnology & Microbiology: Supports controlled experimental setups and culture environments.

- Academic Institutions: Reliable for teaching labs and routine scientific glassware usage.

- General Laboratory Workflow: Provides dependable sealing for titration flasks, storage bottles, reaction vessels, and volumetric containers.