Description

| Catalogue No. | Capacity (ml) |

|---|---|

| 11304/ 01 | 50 |

| 11304/02 | 100 |

| 11304/03 | 250 |

| 11304/04 | 500 |

| 11304/05 | 1000 |

| 11304/06 | 2000 |

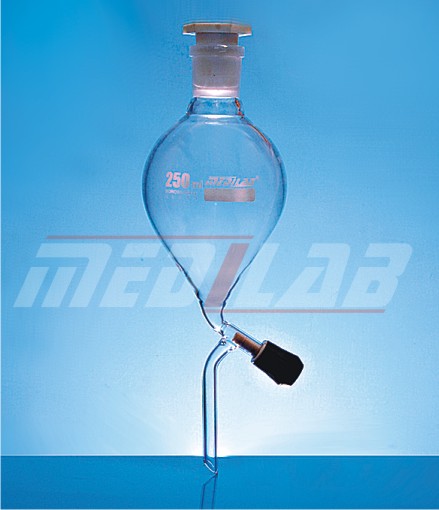

The MEDILAB Pear-Shaped Separating Funnel with Rotaflow Stopcock is a precision liquid-liquid extraction vessel designed for reliable phase separation of immiscible liquids in chemical, pharmaceutical, environmental, and academic laboratories. Its globe/pear geometry provides fast and efficient settling, while the screw-type Rotaflow stopcock ensures smooth, leak-free drainage. Engineered for durability, chemical resistance, and operational safety, this funnel is essential in workflows involving solvent extraction, purification, and analytical sample preparation.

Key Features

- Pear/Globe-Shaped Design for improved phase clarity and faster separation.

- High-Precision Rotaflow Stopcock offering controlled drainage, smooth rotation, and excellent leak resistance.

- Manufactured from Borosilicate Glass 3.3, ensuring superior thermal and chemical durability.

- Complies with ISO 4800 Standards, ensuring global laboratory compatibility.

- Supplied with a PP Stopper, lightweight, chemically inert, and easy to clean.

- Thick, Even-Wall Construction for long operational life and high mechanical strength.

- Clear, Permanent Graduations for accurate, repeatable measurements.

- Corrosion-Resistant Components suitable for a wide range of organic and aqueous solvents.

- Leak-Proof Assembly with screw-type fittings for secure operation during shaking and mixing.

Material Specifications

- Material: High-grade Borosilicate Glass 3.3 (ISO 3585 compliant)

- Thermal Properties: Low thermal expansion coefficient, excellent resistance to thermal shock Suitable for autoclaving and controlled heating

- Chemical Resistance: Highly resistant to acids, alkalis, organic solvents, and corrosive vapours. Non-porous surface prevents contamination and ensures sample integrity

- Mechanical Properties: High strength and scratch resistance. Maintains clarity and structural stability over long-term use

Technical Specifications

- Available Capacities: As per the standard size table

- Stopcock Type: Screw-type Rotaflow stopcock. Chemically resistant, smooth-action key

- Stopper: A Polypropylene (PP) stopper is included. An optional glass stopper is available on request

- Graduations: Durable, easy-to-read markings for precise volume reference

- Tolerance & Accuracy: Manufactured with controlled calibration tolerances as per international glassware standards

- Accessories Included: PP stopper, Rotaflow stopcock (assembled)

Handling & Precautions

- Safe Use: Ensure the stopper and stopcock are firmly secured before shaking. Hold the stopper during mixing to prevent accidental opening

- Cleaning: Rinse immediately after use to prevent residue buildup. Compatible with standard laboratory glassware detergents. Avoid abrasive cleaning materials

- Autoclaving / Temperature Limits: Autoclavable at standard sterilisation cycles. Remove the PP stopper before autoclaving. Avoid sudden temperature shocks to prevent stress fractures

- Dos: Lubricate the Rotaflow stopcock when required. Inspect for chips or cracks before each use. Store vertically to protect the stem

- Don’ts: Do not overtighten the screw stopcock. Do not subject the funnel to open flame or extreme heating

- Best Practices: Air-dry thoroughly before storage. Maintain regular stopcock cleaning to ensure smooth operation

Applications

- Organic Chemistry & Solvent Extraction

- Pharmaceutical and Biopharmaceutical Labs

- Environmental Analysis: Water, soil, and effluent extraction

- Quality Control / Quality Assurance Testing

- Chemical Synthesis & Purification Procedures

- Academic Laboratory Training and Demonstrations

- Biotechnology Sample Preparation

This funnel supports reliable separation of immiscible liquids, washing steps, and purification stages essential across R&D, industry, and analytical environments.