Description

| Catalog No. | Socket Size | Cone Size |

| 11111/1 | 14/23 | 19/26 |

| 11111/2 | 14/23 | 24/29 |

| 11111/3 | 14/23 | 29/32 |

| 11111/4 | 19/26 | 24/29 |

| 11111/5 | 19/26 | 29/32 |

| 11111/6 | 19/26 | 34/35 |

| 11111/7 | 19/26 | 40/38 |

| 11111/8 | 24/29 | 29/32 |

| 11111/9 | 24/29 | 34/35 |

| 11111/10 | 24/29 | 40/38 |

| 11111/11 | 24/29 | 45/40 |

| 11111/12 | 29/32 | 34/35 |

| 11111/13 | 29/32 | 40/38 |

| 11111/14 | 29/32 | 45/40 |

| 11111/15 | 34/35 | 40/38 |

| 11111/16 | 34/35 | 45/40 |

| 11111/17 | 34/35 | 50/42 |

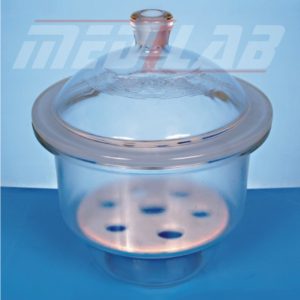

MEDILAB Reduction Adapters are precision-engineered glass connectors designed to join glassware components with different joint sizes. They allow users to transition from a larger cone joint to a smaller socket joint with a secure, leak-proof fit. Ideal for daily laboratory operations, these adapters enhance compatibility, reduce the need for additional apparatus, and ensure smooth integration of workflows in research, chemical processing, and analytical applications.

2. Key Features

- Precision-Ground Joints for accurate, airtight connections between mismatched joint sizes.

- Large Cone Joint at the Base & Smaller Socket Joint at the Top, enabling flexible connectivity.

- High Durability & Thermal Stability due to Borosilicate Glass 3.3 construction.

- Chemical-Resistant Surface is ideal for corrosive or volatile substances.

- Smooth Internal Finish ensuring easy flow and preventing sample contamination.

- Available in Multiple Joint Combinations to suit various lab setups.

- Reusable & Autoclavable for long-term, cost-effective use.

- ISO-compliant manufacturing for consistent quality and dimensional accuracy.

3. Material Specifications

- Material: Borosilicate Glass 3.3

- Thermal Properties: Low thermal expansion coefficient (~3.3 × 10⁻⁶/K), High thermal shock resistance. Suitable for autoclaving and controlled heating

- Chemical Resistance: Resistant to acids, alkalis, solvents, and organic chemicals

- Mechanical Strength: Robust structure and strong ground joints for repeated use

- Standards: Manufactured in compliance with ISO, DIN, and ASTM glassware standards

4. Technical Specifications

- Available Joint Sizes: Common combinations include 14/23 to 34/35 (as per the standard size table). Custom joint configurations available upon request

- Joint Type: Standard taper, precision-ground

- Tolerance: ISO-standard accuracy with tight dimensional control

- Dimensions: Manufactured as per standard laboratory joint specifications

- Accessories: Can be supplied with compatible stoppers, clamps, or adapters (optional)

Handling & Precautions

- Safe Use: Avoid sudden temperature changes to prevent thermal shock. Ensure joints are clean and lightly lubricated when necessary

- Cleaning Instructions: Wash with mild laboratory detergent and rinse with distilled water. Suitable for ultrasonic cleaning

- Autoclaving: Can be autoclaved at standard conditions (121°C, 15 psi)

- Dos: Inspect joints for chips before use. Store in padded trays to prevent breakage

- Don’ts: Do not over-tighten or force joints. Avoid using abrasive cleaning materials

Applications

- Used across chemical, pharmaceutical, biotech, analytical, and academic laboratories

Essential for connecting apparatus with mismatched joints in:

- Distillation setups

- Reaction assemblies

- Filtration and extraction systems

- Heating, cooling, and reflux units

Improves flexibility in lab workflow by reducing the need for uniform joint sizes across glassware