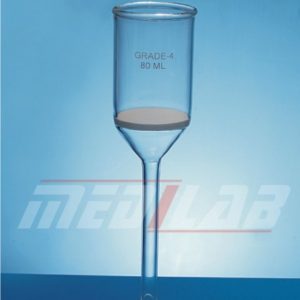

Description

| Catalog No. | Capacity ml |

| 11032/1 | 125 |

| 11032/2 | 250 |

| 11032/3 | 500 |

| 11032/4 | 1000 |

The MEDILAB Gas Washing Bottle is a precision-designed laboratory apparatus used to purify, humidify, or dry gases by passing them through specific liquids or reagents. Manufactured from high-quality Borosilicate Glass 3.3, it ensures excellent chemical resistance and thermal stability for demanding laboratory and industrial environments. This bottle plays a vital role in analytical processes, gas absorption studies, and controlled experiments where consistent gas treatment is essential. Its robust construction and accuracy make it suitable for routine use in research, quality control, and production setups.

Key Features

- High-Purity Construction: Made from Borosilicate Glass 3.3 for superior chemical and thermal resistance.

- Efficient Gas Treatment: Designed to maximise contact between gas and washing media for improved purification.

- Leak-Proof Design: Precision-fitted components ensure secure connections and safe operation.

- Clear Visibility: The Transparent glass body allows easy monitoring of liquid levels and gas behaviour.

- Universal Compatibility: Suitable for various laboratory gas handling systems and absorption setups.

- Durable & Reusable: Ideal for long-term use with high resistance to corrosion, heat, and repeated sterilisation.

- Safe Operation: Smooth edges and accurate ground joints ensure secure assembly and reduced handling risk.

Material Specifications

- Material: Borosilicate Glass 3.3

- Properties: High thermal resistance (low coefficient of thermal expansion), excellent chemical durability against acids, alkalis, and solvents Superior mechanical strength under regular laboratory handling

- Standards Compliance: Manufactured as per international glass quality standards. Suitable for autoclaving and high-temperature applications

Technical Specifications

- Available Capacities: As per the standard size table

- Design Options: With a fritted diffuser, With a plain inlet tub,e With an interchangeable ground joint

- Dimensions: Standard heights and diameters are designed for compatibility with laboratory stands and clamps

- Tolerance/Accuracy: Manufactured with precision dimensional tolerances for airtight fittings

- Calibration: Not applicable (non-volumetric apparatus)

- Accessories Included: Glass inlet and outlet tubes, Diffuser/fritted sparger (as per selected model), Optional screw cap or stopper

Handling & Precautions

- Safe Use: Handle with care; avoid sudden temperature changes to prevent thermal shock. Ensure secure connection of tubes before gas flow.

- Cleaning: Wash with mild laboratory detergent and rinse with distilled water. Compatible with ultrasonic cleaners.

- Sterilisation: Autoclavable up to 121°C; dry heat sterilisation only if gradual heating is used.

- Do’s & Don’ts: Do: Inspect for cracks before each use. Do: Use appropriate clamps to support the bottle. Don’t: Expose to open flame or excessive mechanical stress. Don’t: Use with highly reactive gases without a proper safety assessment.

- Best Practices: Maintain proper liquid level for effective gas absorption. Replace chemicals or reagents regularly for consistent performance.

Applications

- Research Laboratories: Gas purification, humidification, and absorption experiments.

- Pharmaceutical & Chemical Industries: Removal of impurities or moisture from gases during analysis and production.

- Biotechnology & Life Sciences: Controlled gas introduction in biological systems.

- Environmental Testing Labs: Gas scrubbing and emission analysis.

- Academic Institutions: Teaching and demonstration of gas–liquid interaction principles.

- QC/QA Labs: Reliable setup for gas treatment in analytical workflows.