Description

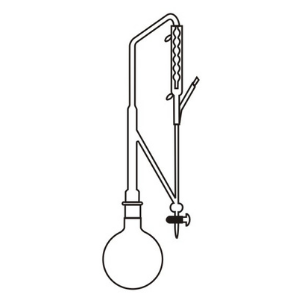

The MEDILAB Essential Oil Determination Apparatus, also known as the Clevenger Apparatus, is a precision glass assembly designed for the quantitative determination of essential oils in plant materials. It operates on the principle of steam distillation, enabling accurate separation and measurement of volatile oils from botanical samples. This apparatus is a fundamental tool in chemical, pharmaceutical, and agricultural laboratories where high-accuracy extraction and quality assessment are essential.

Key Features

- Manufactured from high-quality Borosilicate Glass 3.3 for maximum chemical and thermal resistance.

- Precision-designed condenser and receiver ensure efficient oil separation and accurate volumetric measurement.

- Integrated stopcock at the receiver for easy drainage and controlled collection.

- Suitable for continuous operation during long distillations without performance loss.

- Excellent transparency for clear observation of distillate and oil-water separation.

- Leak-proof joints ensure safe handling of steam and volatile compounds.

- Compatible with commonly used solvent entrainers, including those heavier than water.

Material Specifications

Material: Borosilicate Glass 3.3

Key Properties:

- High thermal shock resistance (Low thermal expansion coefficient 3.3 × 10⁻⁶/K)

- Outstanding chemical resistance to oils, solvents, acids, and organic compounds

- High mechanical strength suitable for repeated steam distillation cycles

- Smooth, non-porous surface ensuring easy cleaning and long service life

Standards Compliance: - Manufactured in accordance with ISO, DIN, and ASTM laboratory glassware standards

- Suitable for regulatory and quality-controlled laboratory environments

Technical Specifications

- Available Capacities (Catalogue No.): As per the standard size table

- Dimensions: Standard Clevenger configuration with vertical condenser, oil receiver, return tube, and round-bottom flask connection. Custom dimensions available on request

- Accuracy / Tolerance: High-precision graduated receiver for accurate oil measurement

- Accessories Included: Graduated oil receiver with stopcock, Condenser unit, Return tube, Compatible joint fittings. Optional: Round-bottom flask, clamps, stands (upon request)

Handling & Precautions

- Ensure proper setup and secure all joints before initiating steam distillation.

- Clean using mild detergents; avoid abrasive materials that may scratch glass surfaces.

- Suitable for autoclaving up to 121°C; avoid direct flame or rapid temperature shifts.

- Do not expose glass to sudden cooling while hot (to prevent thermal stress).

- Store in a dry, stable location with adequate support to prevent impact or tipping.

- Ensure continuous water flow during distillation to maintain optimal condenser efficiency.

Applications

- Essential oil extraction from plant materials in research, quality control, and production labs

- Agricultural and botanical testing for volatile oil content

- Pharmaceutical and cosmetic industry formulation studies

- Food and flavor industry evaluation of aromatic compounds

- Academic laboratories for teaching steam distillation principles

- Chemical, biotech, and QC/QA labs performing routine volatiles analysis

This apparatus plays a vital role in purity testing, formulation development, and research involving natural product chemistry.