Description

| Catalogue No. | Inner Diameter | Wall Thickness | Outer Diameter |

| (ID in MM) | (W in MM) | (OD in MM) | |

| 19808/1 | 2 | 1 | 4 |

| 19808/2 | 3 | 1 | 5 |

| 19808/3 | 3 | 1.5 | 6 |

| 19808/4 | 4 | 1 | 6 |

| 19808/5 | 4 | 1.5 | 7 |

| 19808/6 | 4 | 2 | 8 |

| 19808/7 | 5 | 1 | 7 |

| 19808/8 | 5 | 1.5 | 8 |

| 19808/9 | 6 | 1 | 8 |

| 19808/10 | 6 | 1.5 | 9 |

| 19808/11 | 6 | 2 | 10 |

| 19808/12 | 6 | 3 | 12 |

| 19808/13 | 7 | 1.5 | 10 |

| 19808/14 | 7 | 2 | 11 |

| 19808/15 | 8 | 1.5 | 11 |

| 19808/16 | 8 | 2 | 12 |

| 19808/17 | 8 | 3 | 14 |

| 19808/18 | 9 | 2 | 13 |

| 19808/19 | 10 | 2 | 14 |

| 19808/20 | 10 | 3 | 16 |

| 19808/21 | 12 | 2 | 16 |

| 19808/22 | 12 | 3.5 | 19 |

| 19808/23 | 14 | 3 | 20 |

| 19808/24 | 15 | 4 | 23 |

| 19808/25 | 16 | 3 | 22 |

| 19808/26 | 25 | 4 | 33 |

Available in 10-meter coils.

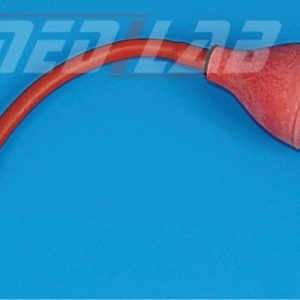

Silicone Rubber Tubing is a high-purity, flexible, and thermally stable tubing designed for demanding laboratory, pharmaceutical, medical, and industrial applications. Its excellent temperature resistance and biocompatibility make it ideal for fluid handling, air transfer, peristaltic pumping, and general utility use. The tubing maintains stability under extreme temperatures, ensuring reliable performance in controlled environments.

Key Features

- Excellent thermal stability with an operating range from –50°C to 250°C

- High flexibility and kink resistance for smooth fluid or gas transfer

- Odorless, non-toxic, and physiologically inert

- Resistant to UV, ozone, moisture, and long-term environmental exposure

- Smooth internal bore ensures consistent flow and minimizes particle adherence

- Ideal for peristaltic pumps due to elasticity and mechanical durability

- Shore Hardness: 45A for optimal balance between flexibility and structural strength

Material Specifications

- Material: 100% high-purity silicone rubber

- Thermal Properties:

Operational temperature: –50°C to 250°C

High thermal shock resistance - Chemical Properties:

Non-reactive, suitable for sensitive media

Resistant to mild chemicals, water, oils, ozone, and solvents - Mechanical Properties:

High tear strength and elongation

Maintains elasticity under repeated stress - Compliance & Standards:

Meets pharmaceutical and laboratory-grade safety requirements

Technical Specifications

- Available Inner Diameters: Multiple sizes ranging from small-bore to large-bore tubing

- Outer Diameter & Wall Thickness: Customizable based on laboratory or industrial requirements

- Hardness: 45 Shore A

- Tolerance: Standard precision tolerance suitable for lab-grade tubing

- Configuration: Straight lengths or coils

- Accessories (optional): Connectors, clamps, stoppers, and adaptors compatible with silicone tubing

Handling & Precautions

- Suitable for autoclaving and repeated sterilization cycles

- Avoid contact with concentrated acids or aggressive solvents

- Store in a cool, dry area away from direct UV exposure to maintain elasticity

- Clean using mild detergents or laboratory-approved cleaning agents

- Do not exceed recommended temperature limits to prevent degradation

- Ensure proper fitting to avoid strain or tearing during use

- Replace tubing periodically in high-pressure or long-duration applications

Applications

- Pharmaceutical & Biotech: Media transfer, peristaltic pumping, sterile fluid handling

- Chemical Laboratories: Gas and liquid transfer, distillation, general utility connections

- Medical & Clinical: Airlines, drainage, non-invasive fluid transport

- Food & Beverage: Food-grade fluid handling, sampling, dispensing

- Industrial: Machinery lubrication lines, insulation, vacuum applications

- Academic & Research Institutions: Teaching labs, experimental setups, prototype systems

Silicone Rubber Tubing plays a vital role in laboratory and industrial workflows due to its purity, durability, thermal resistance, and compliance with global quality standards.