Description

| Catalogue No. | Flask(ml) |

|---|---|

| 11018/01 | 1000 |

| 11018/02 | 2000 |

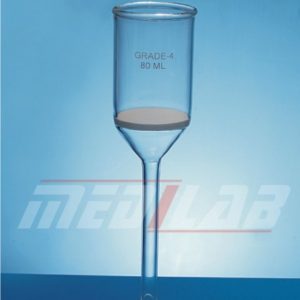

The MEDILAB Membrane Filter Holder Assembly with Silicon Cork is a high-performance filtration unit designed for precise membrane-based vacuum filtration. Engineered for microbiological analysis, sterility testing, and particulate separation, it ensures clean, consistent, and contamination-free filtration results. Its robust Borosilicate Glass 3.3 construction and secure clamping system make it ideal for demanding laboratory and industrial environments where accuracy and reliability are essential.

Key Features

- High-quality Borosilicate Glass 3.3 filtration flask designed to withstand high vacuum pressure.

- 47 mm membrane filter support, compatible with standard laboratory membrane filters.

- 300 mL funnel with PP lid for dust-free, controlled filtration.

- Durable anodized aluminum clamp ensures strong, leak-proof sealing between funnel and base.

- Silicon cork provides a stable, chemical-resistant interface between components.

- Laser-cut foam protective packaging for safe international transportation.

- Chemical-resistant enamel printing for long-lasting markings and readability.

- Smooth surface finish allows effortless cleaning and sterilisation.

- Reliable performance in sterile, analytical, and high-purity workflows.

Material Specifications

- Material: Heavy-Duty Borosilicate Glass 3.3

- Thermal Properties: Exceptional thermal resistance Low thermal expansion (3.3 × 10⁻⁶ /°C), preventing stress cracks during heating/cooling

- Chemical Resistance: Inert to most chemicals, acids, and solvents. Safe for use with microbiological media and pharmaceutical samples

- Mechanical Strength: Thick-walled flask supports sustained vacuum conditions

- Compliance: Manufactured in accordance with relevant laboratory glassware standards

Technical Specifications

- Membrane Diameter: 47 mm

- Funnel Capacity: As per the standard size table

- Filtration Flask Capacity: As per the standard size table

- Clamp: Anodized aluminum clamp for secure assembly

- Accuracy/Tolerance: Standard laboratory glassware tolerance (ISO compliant)

- Sterilisation: Glass components: Autoclavable PP lid: Autoclavable at standard autoclave settings. Clamp: Not recommended for autoclaving due to anodized finish

- Included Accessories: Funnel with PP lid, Membrane filter holder base, Anodised aluminium clamp, Borosilicate glass filtration flask, Silicon cork seal

Handling & Precautions

- Safe Use: Ensure the clamp is firmly tightened before applying the vacuum. Inspect the glass for chips or cracks before each use.

- Cleaning: Rinse immediately after filtration to prevent residue buildup. Use mild detergents; avoid abrasive cleaners.

- Autoclaving/Heating: Autoclave only glass and PP components. Do not expose the anodised aluminium clamp to prolonged high temperatures.

- Do’s & Don’ts: Do: Handle glassware with both hands during setup. Do: Replace worn silicon corks for optimal sealing. Don’t: Use hydrofluoric acid or other agents known to etch glass. Don’t: Apply excessive torque to the clamp.

- Best Practices: Store the assembly dismantled to extend component life. Periodically check sealing surfaces for wear.

Applications

- Microbiological Laboratories: Microbial load testing, sterility checks, media filtration.

- Pharmaceutical & Biotech: Filtration of buffers, reagents, and sterile solutions.

- Environmental Testing: Water, wastewater, and particulate analysis.

- Chemical & Analytical Labs: Solvent filtration, purification, and sample preparation.

- QC/QA Laboratories: Routine filtration for quality control workflows.

This assembly plays a critical role in ensuring accurate, repeatable, and contamination-free filtration across scientific and industrial sectors.