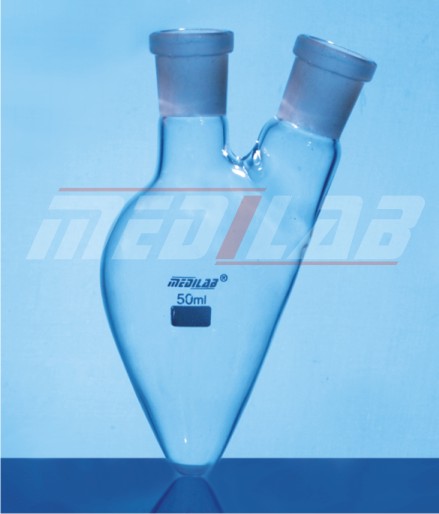

Description

| Catalogue No. | Nominal capacity ml | Socket size | Centre socket | Side Socket | App. Overall, hmm. | Pack of |

| 11148/1 | 50 | 14/23 | 14/23 | 14/23 | 100 | 1 |

| 11148/2 | 100 | 14/23 | 14/23 | 14/23 | 130 | 1 |

The MEDILAB Pear-Shaped Two-Neck Flask is a precision-engineered laboratory vessel designed for heating, mixing, distillation, and controlled chemical reactions. Its unique pear-shaped body promotes efficient mixing and minimizes sample loss, while the dual neck configuration allows simultaneous attachment of condensers, thermometers, adapters, or other lab apparatus. Made from high-quality Borosilicate Glass 3.3, this flask ensures excellent thermal resistance, chemical durability, and long operational life in demanding laboratory and industrial settings.

Key Features

- Two-Neck Design: Facilitates multi-step experimental setups, enabling parallel connections for reflux, temperature monitoring, and reagent addition.

- Pear-Shaped Body: Enhances evaporation efficiency and concentrates solutions effectively.

- High Thermal Stability: Withstands thermal shocks during heating and cooling cycles.

- Chemical Resistance: Suitable for a wide range of acids, solvents, and reagents.

- Precision Ground Joints: Leakproof assembly and compatibility with all standard joint glassware.

- Clear Visibility: Excellent transparency for monitoring reaction progress.

- Durable Construction: Manufactured using thick, uniform Borosilicate Glass 3.3 for long service life.

- Autoclavable & Reusable: Designed for repeated sterilisation and daily laboratory use.

Material Specifications

- Material: Borosilicate Glass 3.3

- Thermal Properties: High resistance to thermal shock; low thermal expansion coefficient (approx. 3.3 × 10⁻⁶ /°C).

- Chemical Properties: Inert to most chemicals, solvents, and corrosive agents; non-porous and contamination-resistant.

- Mechanical Strength: High mechanical stability and durability for repeated handling.

- Compliance: Manufactured according to international laboratory glassware standards (ISO / DIN).

Technical Specifications

- Available Capacities: As per the standard size table

- Joint Options: Two standard ground joints (main neck + side neck) as per ISO/DIN specifications.

- Design: Pear-shaped body with a round bottom for uniform heating.

- Tolerance: High dimensional and volume accuracy suitable for analytical and preparative applications.

- Calibration: Supplied non-calibrated (calibration options available upon request).

- Accessories (Optional): Stoppers, adapters, and compatible joint accessories are available upon request.

Handling & Precautions

- Safe Usage: Always support the flask properly when connecting multiple apparatus.

- Cleaning: Wash with mild laboratory detergent; avoid abrasive materials that may scratch the glass.

- Heating: Suitable for use on heating mantles, water/oil baths, or controlled flame sources.

- Autoclaving: Fully autoclavable at standard sterilisation temperatures.

- Dos: Use proper joint lubrication if required. Inspect joints and necks before use

- Don’ts: Do not subject the flask to sudden extreme temperature changes. Avoid using it with highly alkaline solutions at high temperatures

- Best Practices: Allow gradual heating/cooling and store in a cushioned rack to prolong glass life.

Applications

- Chemical Synthesis & Reactions – Ideal for refluxing, distillation, boiling, and controlled reactions.

- Pharmaceutical & Biotech Labs – Suitable for active ingredient development, purification, and formulation studies.

- Academic & Research Institutions – Used in organic chemistry, analytical chemistry, and laboratory teaching.

- Quality Control / Quality Assurance Labs – Supports routine analysis, solution preparation, and controlled heating tasks.

- Industrial R&D – Reliable for pilot-scale experiments and process development.