Description

| Catalogue No. | Capacity ml | Dia. | D1 mm | Height mm |

| 11004/1 | 25 | 42 | 31 | 70 |

| 11004/2 | 50 | 51 | 34 | 85 |

| 11004/3 | 100 | 64 | 34 | 105 |

| 11004/3.1 | 150 | – | – | – |

| 11004/4 | 250 | 85 | 50 | 140 |

| 11004/5 | 500 | 105 | 50 | 175 |

| 11004/6 | 1000 | 131 | 50 | 220 |

| 11004/7 | 2000 | 166 | 76 | 276 |

| 11004/8 | 3000 | – | – | – |

| 11004/9 | 5000 | – | – | – |

| 11004/10 | 10000 | – | – | – |

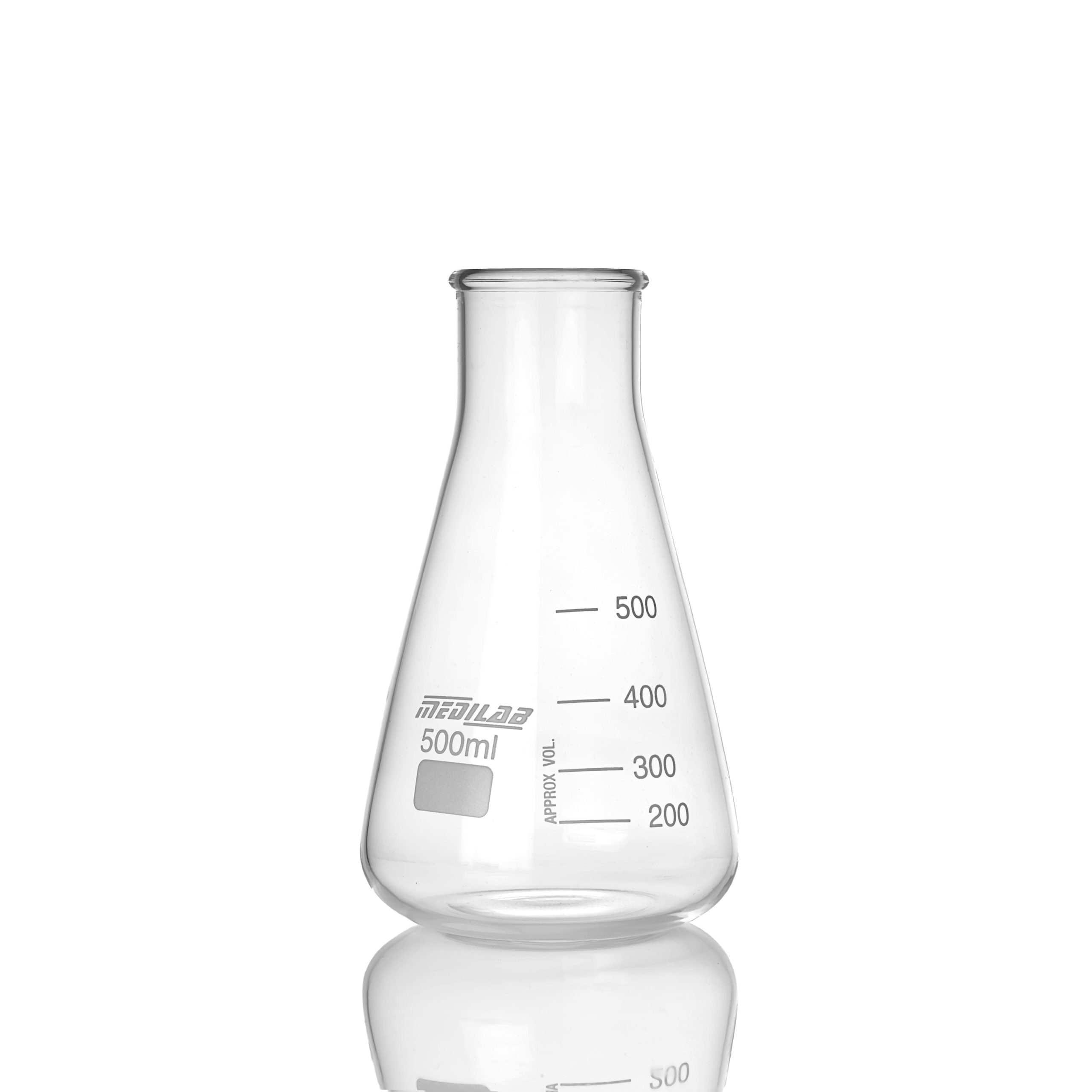

The MEDILAB Erlenmeyer Flask (Wide Neck) is a conical laboratory flask designed for safe mixing, heating, culturing, and storage of liquid samples. Its wide-mouth design ensures easy filling, transfer, and cleaning—ideal for routine lab operations and industrial-scale procedures. With excellent thermal and chemical durability, this flask is an essential tool for research labs, universities, pharma manufacturing, microbiology, and QC/QA environments demanding reliable and repeatable performance.

Key Features

- Wide Neck Design for effortless pouring, loading of reagents, and use with large stir bars or pipettes.

- Heavy-Duty Borosilicate Glass 3.3 ensures exceptional thermal shock resistance and a long service life.

- Uniform Wall Thickness for improved strength and reduced risk of breakage.

- Conical Shape supports efficient mixing and minimises sample loss during swirling.

- Graduated Markings (optional) for quick and approximate volume checks.

- Autoclavable & Heat-Resistant for sterilisation and high-temperature applications.

- Chemical Resistant against acids, alkalis, solvents, and lab reagents.

- Compatible with Standard Rubber/Cork Stoppers and common laboratory clamps and supports.

- Smooth, Fire-Polished Rim for safe handling and reduced chipping.

Material Specifications

- Material: Borosilicate Glass 3.3 (Neutral Glass, Low Expansion)

- Thermal Expansion Coefficient: 3.3 × 10⁻⁶ /°C

- Temperature Range: –70°C to +500°C (with proper heating protocols)

- Autoclavable: Yes, at 121°C

- Chemical Resistance: High resistance to acids, alkalis, salts, and organic solvents

- Standards Conformity: Meets ISO 1773, DIN and relevant international laboratory glassware standards

- Mechanical Properties: High tensile strength, excellent mechanical stability under repeated use

Technical Specifications

- Available Capacities: (As per the standard size table)

- Dimensions:

Diameter, height, and neck diameter vary by capacity (custom size charts available on request) - Graduation Accuracy:

Approximate graduations (if supplied), suitable for routine volume estimation

Not intended for precise volumetric measurements unless calibrated - Calibration (Optional):

ISO-certified calibration available upon request - Accessories (Optional): Rubber stoppers, vented caps, clamps, stands, and protective sleeves

Handling & Precautions

- Always preheat gradually to avoid thermal shock; avoid rapid temperature changes.

- Do not heat on an open flame unless supported with a wire gauze.

- Clean using mild detergents; avoid abrasive scrubbing to preserve clarity.

- Autoclave only when the flask is clean, dry, and uncapped.

- Use appropriate clamps or holders when heating or swirling hot liquids.

- Inspect regularly for chips or cracks; discontinue use immediately if damage is found.

- Store in dry, dust-free conditions to maintain the product’s long life.

Applications

- Pharmaceutical & Chemical Labs: Solution preparation, titration support, reagent storage, and sample heating.

- Microbiology & Biotech: Culture media preparation, microbial growth, and shaking/incubation applications.

- Academic & Research Institutions: Teaching experiments, chemical reactions, qualitative analysis.

- QC/QA Laboratories: Routine testing workflows, sample analysis, and controlled environment work.

- Industrial R&D: Mixing, formulation development, and small-scale pilot studies.

- Plays a vital role in daily lab workflows requiring reliable mixing, heating, and safe reagent handling.