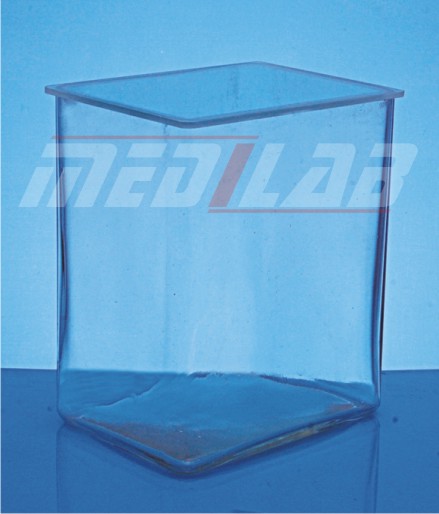

Description

| Catalogue No. | Size (mm) |

| 11020/6 | 140x140x220 |

| 11020/7 | 170x130x210 |

| 11020/8 | 225x125x225 |

| 11020/9 | 250x150x250 |

The MEDILAB Chromatographic Tank, also known as a Developing Chamber, is a precision-crafted glass vessel designed for Thin Layer Chromatography (TLC) solvent development. It provides a controlled environment for mobile phase saturation, ensuring sharp, reproducible, and high-resolution chromatographic separations. Widely used in research, pharmaceutical QC, chemical analysis, and academic labs, this chamber is essential for reliable compound identification and purity testing.

Key Features

- Manufactured from premium Borosilicate Glass 3.3 for superior chemical resistance and thermal stability.

- Ensures uniform solvent vapour saturation for accurate and reproducible TLC results.

- Smooth, stress-free construction minimises streaking and solvent disturbances.

- Airtight lid design (depending on model) to prevent solvent evaporation and maintain consistent developing conditions.

- Excellent visibility for monitoring solvent level and plate positioning.

- Available in both rectangular and cylindrical models to suit diverse laboratory workflows.

- Resistant to acids, alkalis, organic solvents, and routine lab reagents.

- Robust and durable design ideal for routine analytical and research work.

Material Specifications

- Material: Borosilicate Glass 3.3

- Thermal Properties: High thermal shock resistance, Low thermal expansion coefficient (~3.3 × 10⁻⁶ /K)

- Chemical Resistance: Highly resistant to most acids, solvents, and chemicals. Non-reactive surface for high-purity analytical applications

- Mechanical Strength: Stress-free, annealed construction for durability in repeated daily use

- Standards Compliance: Manufactured in accordance with ISO 3585 (Borosilicate Glass 3.3 standard). Follows international laboratory glassware norms (ISO / DIN equivalents)

Technical Specifications

- Available Variants: Rectangular TLC Developing Chambers, Cylindrical TLC Developing Chambers

Typical Specifications:

- Wall Thickness: Uniform, optimised for mechanical stability

- Lid Type: Ground glass or flat glass lid (depending on model)

- Tolerance: Within standard lab glassware dimensional tolerance

- Calibration: Not applicable (non-volumetric instrument)

- Accessories (optional): Glass rods, TLC plate holders, Chamber liners

Handling & Precautions

- Handle with care to avoid sudden impacts or thermal shocks.

- Clean using mild laboratory detergents; avoid abrasive materials that may scratch the glass.

- Compatible with acetone, ethanol, and most solvent cleaning agents.

- Do not expose to open flame or extreme direct heat; maximum recommended heating: up to 200°C (dry heat).

- Allow gradual heating and cooling to maintain glass integrity.

- Ensure the chamber is completely dry before adding solvent to avoid contamination.

- Store in a well-padded, dust-free location when not in use.

Applications

- Pharmaceutical QC & QA: Impurity profiling, identity testing, purity checks.

- Chemical & Analytical Laboratories: Separation of organic and inorganic compounds.

- Biotechnology & Life Sciences: Monitoring biomolecules, pigments, amino acids, and metabolites.

- Academic & Research Institutions: TLC training, method development, and routine chromatographic studies.

- Industrial Quality Testing: Dyes, polymers, oils, adhesives, and fine chemicals.

- Essential for any workflow involving Thin Layer Chromatography (TLC) or solvent development.